Early Imari

初期伊万里

Home > Fine Arts > Japanese Antique (To the Artworks Information Page)

Early Imari

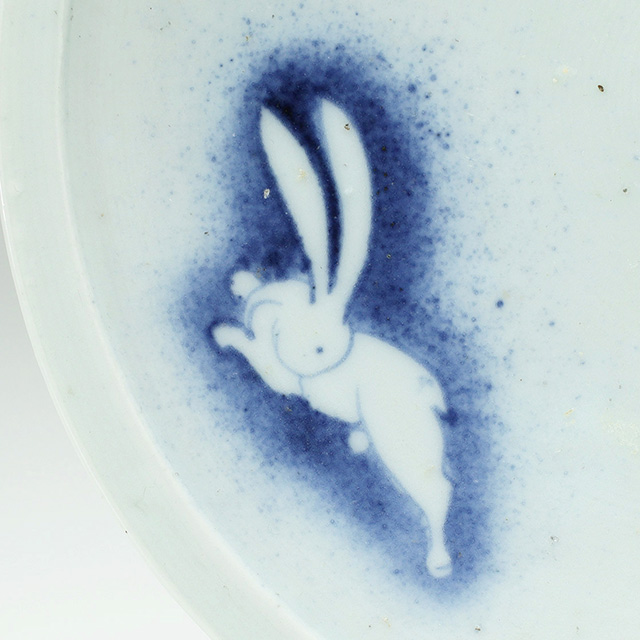

Early imari are the first japanese porcelain wares, thought to have emerged in 1616. Until the middle 17th century, potters used “Single Fire Glazing”, where bisque firing at 900℃ is skipped, and instead it is glaze fired at a high temperature of 1,300℃ right after shaping the clay. After bisque firing was incorporated in the late 17th century, deformations and cracks during the firing process became less frequent. As heat resistant containers called saggar that protect wares that are being fired in the kiln were still not being used, some wares have ash, iron, and other residual particles inside the kiln attached to them. Additionally, coarse sand was laid on the bottom of the kiln to prevent the wares from sticking to it. As such, many of the wares have coarse sand attached to the foot ring at the bottom of the wares. Porcelain making such as these were led by korean potters brought to japan, but enamel decorations were inspired by china’s jingdezhen porcelain during the latter part of the ming dynasty, and in the beginning, japanese potters repeatedly conducted trial and error to come up with a unique japanese style. Very few types of early imari have been found with inscriptions that denote the names of authors, firing kilns, and trademarks. Those that do have inscriptions were done by potters who simply copied the inscriptions on chinese porcelain and did not know how to write nor the meaning of the words, so many of them were incomprehensible and had mistakes or omissions. However, the simple yet profound enamel decorations by potters on their wares are one of the greatest charms of early imari. While the techniques that went into them were still rough on the edges, they portray a sense of innocence and boldness that is not seen in perfected imari ware. “Beauty in Imperfection” is therefore the greatest charm of early imari, which embodies a unique warmth and mildness expressed through the glaze, similar to yi dynasty Porcelain.

Yi Sam-Pyeong and The Birth of Imari Ware

During the japanese invasions of the korean peninsula during 1592-1598, the korean potter Yi Sam-Pyeong(japanese name:Kanagae Sanbee) was brought to japan by the army of Naoshige Nabeshima’s retainer, Taku Nagatonokami Yasutoshi and he was ordered by yasutoshi to make porcelain, so he started firing porcelain at the tojin koba kiln in the outskirts of what is now taku, saga. After that, he moved to the koraidani kiln. Yi Sam-Pyeong took on the japanese name “Kanagae Sanbee”, after the name of his hometown, kanagae, chungcheong province, korea. In order to create porcelain that he made in his home country, he asked permission from Yasutoshi to find white magnetite inside the domain and founded arita ware at the dawn of the 17th century. Yi Sam-Pyeong found white magnetite in izumiyama in 1616. He built a kiln in tengudani and succeeded in making porcelain”, it is written in the “Kanagae Family Records” in 1807, but archeological studies and research found that potters brought over to japan from korea other than Yi Sam-Pyeong may have already started making porcelain earlier in the 1610s in the western part of arita. These wares made in the 17th century are the early-imari, the first porcelains of japan. Thereafter, under the governance of the saga domain, the production of imari ware was expanded, and production was centered in the arita region. The major distinction of this production center was its implementation of advanced production techniques from abroad. One of the advanced techniques brought from the korean peninsula was the large scale climbing kiln which did not exist in japan at the time. It has a high heat storage ratio and is able to keep the kiln temperature relatively stable. The efficiency of the climbing kiln, as well as the versatile and excellent craftsmanship of the potters brought over from korea that allowed them to conform to the preferences of japan’s population, drove the competitiveness of arita against other traditional forms of craft, despite being a newly established production center. Additionally, another factor that contributed to the success of imari ware was the direct incentivization of hizen pottery by the feudal lord of the saga domain. When production started to stabilize around 1624, Yi Sam-Pyeong was assigned to manage and control the white magnetite quarry in izumiyama, improving the management of the magnetite quarry and giving preferential treatment to porcelain artisans. This political intervention by the lord of the saga domain tipped the scales of the pottery industry in the direction of porcelain wares. The arita ware industry developed exponentially and this had a severe impact on existing pottery production centers, resulting in the rapid decline of other types of pottery, including karatsu ware. Yi Sam-Pyeong is honored as “The Father of Porcelain” for his achievements in laying down the foundations of the arita ware industry, and a monument was built in his honor.

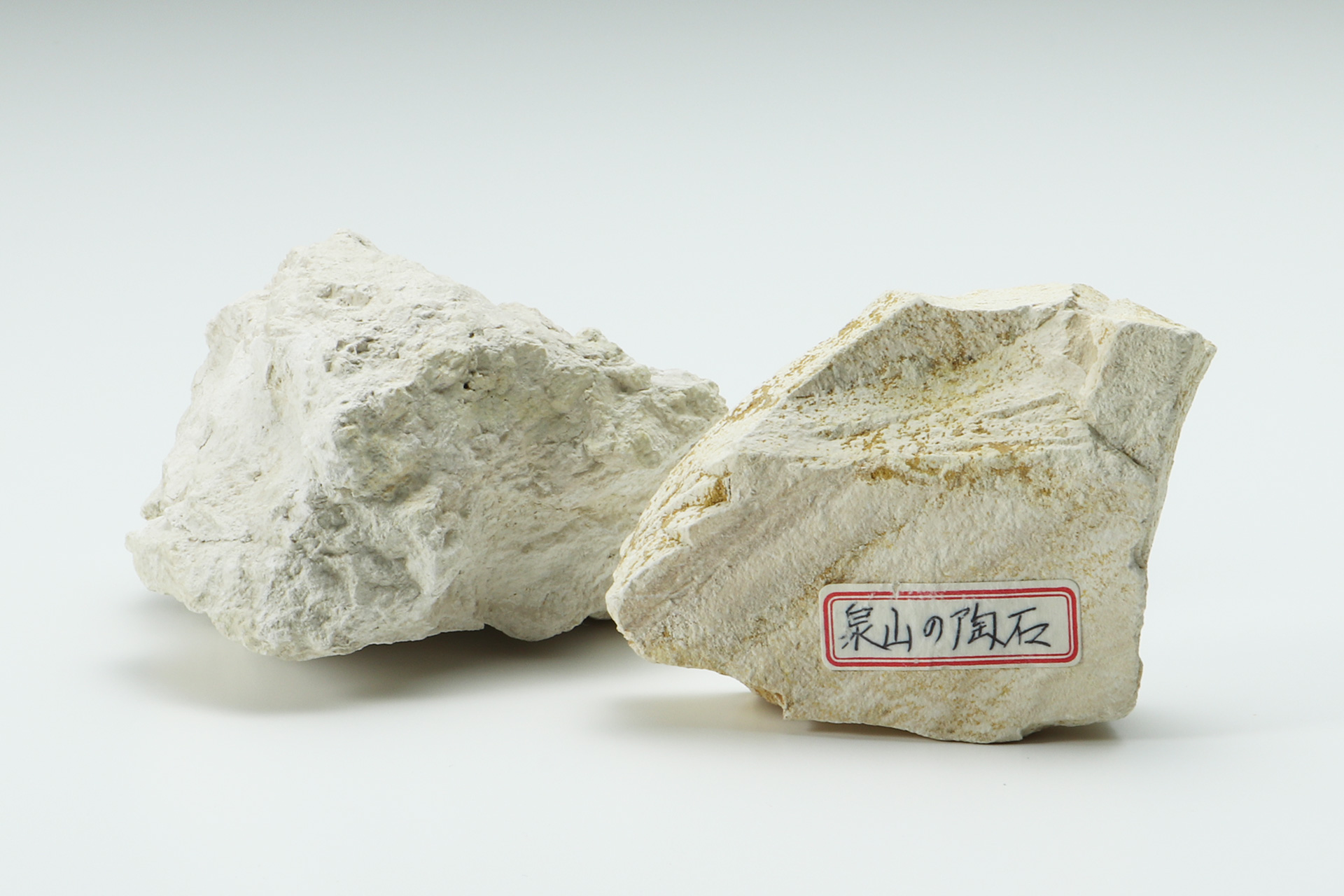

Arita Izumiyama

Arita Izumiyama is a magnetite quarry located in izumiyama, arita machi, nishimatsuura district, saga. It has been mined for white magnetite, an ingredient for porcelain since the beginning of the edo period, and helped develop arita as a porcelain production center. The “Kanagae Family Records” written in 1807 says that Yi Sam-Pyeong found the izumiyama quarry. This document is a family record submitted to the saga domain regarding their mining rights at the izumiyama quarry. The fact that the kanagae family had special mining rights backs the story that Yi Sam-Pyeong found the izumiyama quarry. Magnetite quarries were called “Lumber Yards” during the edo period, and guardhouses were set up to monitor the movement of magnetite out of the quarry. In arita sarayama, the izumiyama magnetite was distinguished by quality and the high quality magnetite from the inner quarries were not allowed to be delivered outside of the area. As it had rich reserves, izumiyama was able to support the production of arita ware in the edo period, but amakusa, kumamoto emerged later on as a high quality supplier of magnetite and supported the production of porcelain on larger scales. Izumiyama is said to have “turned a single mountain into pottery over 400 years.”

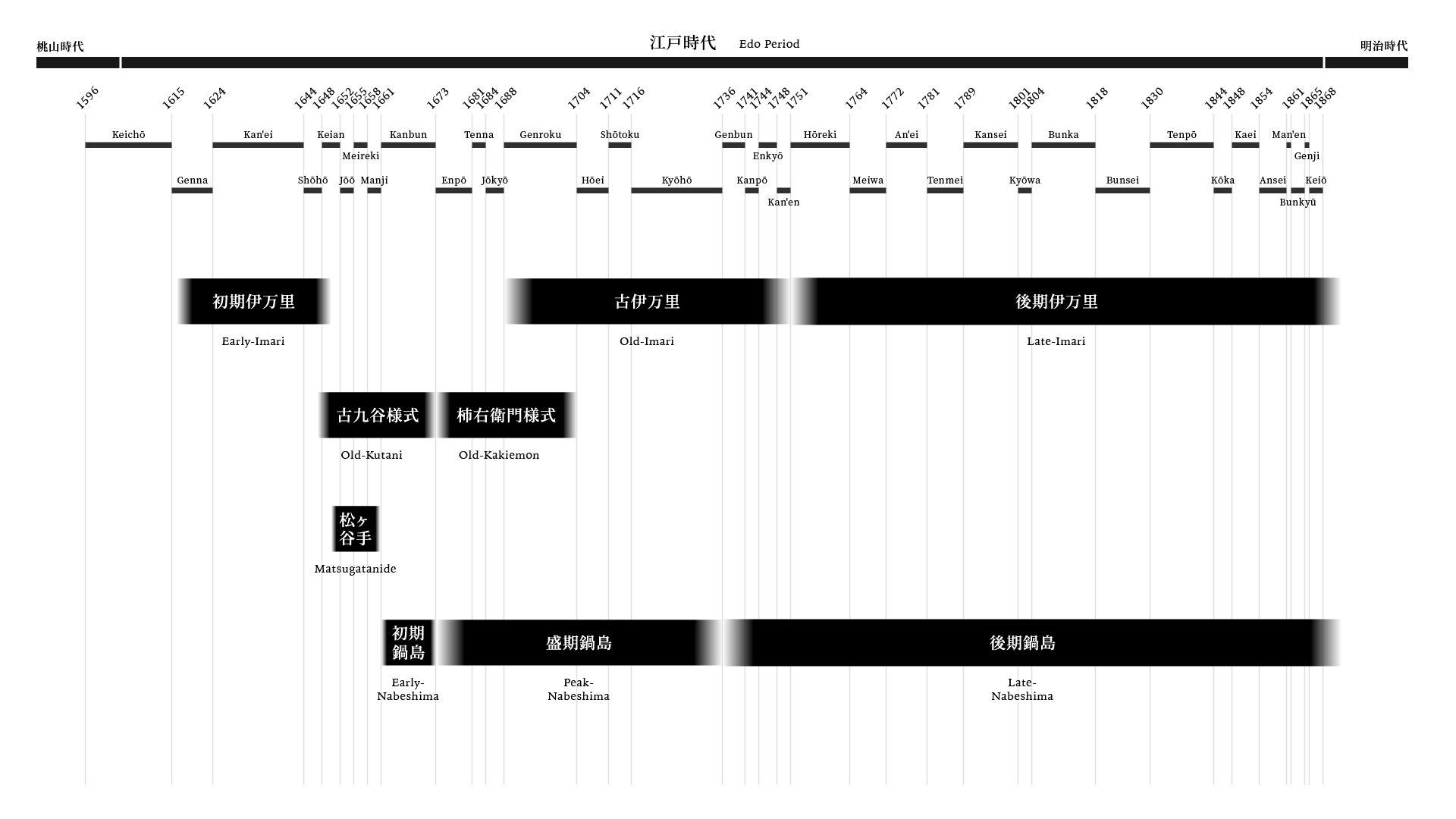

About Imari Ware

Hizen porcelain was founded by potters brought over to japan from korea during the japanese invasions of the korean peninsula from 1592-1598. Hizen is an area within the present saga and nagasaki prefectures. Highly influenced by china’s jingdezhen porcelain, in the 17th century, they created a style of pottery similar to ancient chinese wares but with unique japanese features. The birth of imari ware almost coincides with the start of the edo shogunate, so bold and magnificent wares were produced during the early periods of the shogunate, but this style started to wane at the peak of the Genroku era(1688-1704). The ups and downs of the ceramic trend closely followed the rise and fall of the shogunate. “Imari Ware” refers to porcelain made in sarayama, arita during the edo period, which was delivered to all parts of japan by sea from imari port, thus the name. It was referred to in the haikai textbook, “Kefukigusa”, as “Karatsu Imari Pottery”. This is the first time it was referred to in writing. Somewhere along the way, it became officially known as “Hizen Arita Ware”, and called “Imari Ware” by traders of pottery as a reference to the port it came from. It was only in the taisho period that hizen porcelain was divided into “Imari Ware” and “Nabeshima Ware” and given proper recognition as art. Other than the wealthy in japan, royal families and nobles of europe were also charmed by the porcelain produced in arita, saga, leaving a major mark in the history of japan’s ceramics industry.

We sell and purchase Early Imari

We have a physical shop in Hakata-ku, Fukuoka City, where we sell and purchase "Early Imari" works. Drawing on a long career and rich experience in dealing, we promise to provide the finest service in the best interests of our customers. With the main goal of pleasing our customers, we will serve you with the utmost sincerity and responsibility until we close the deal.