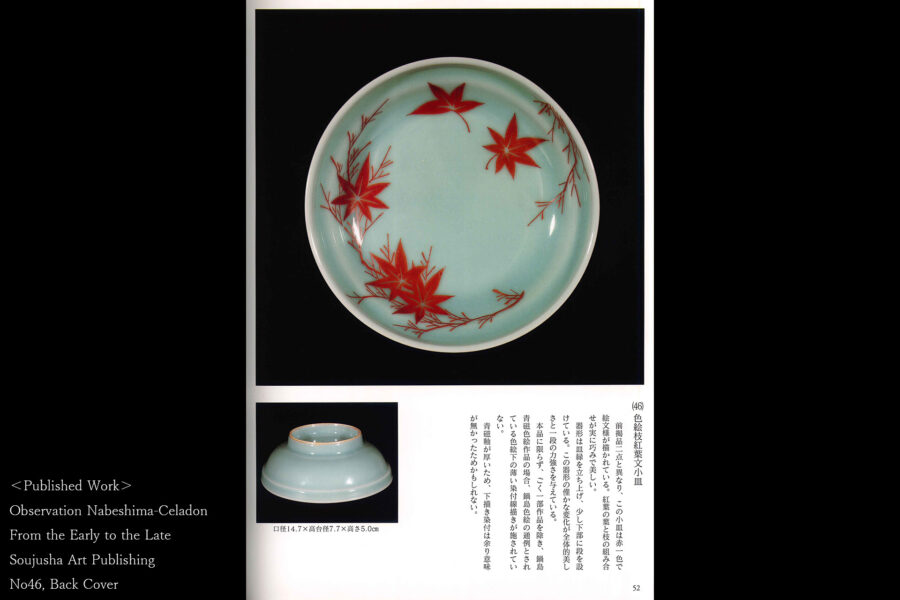

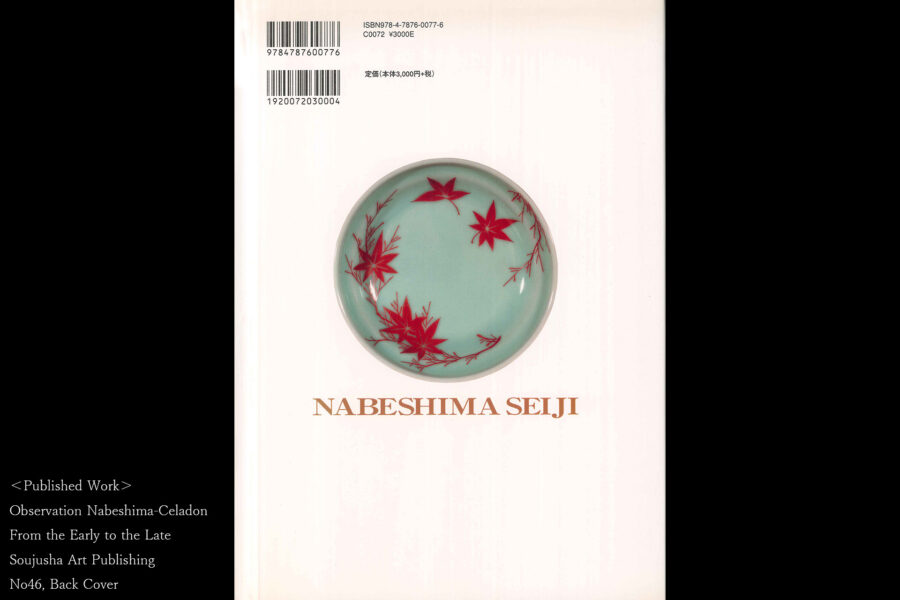

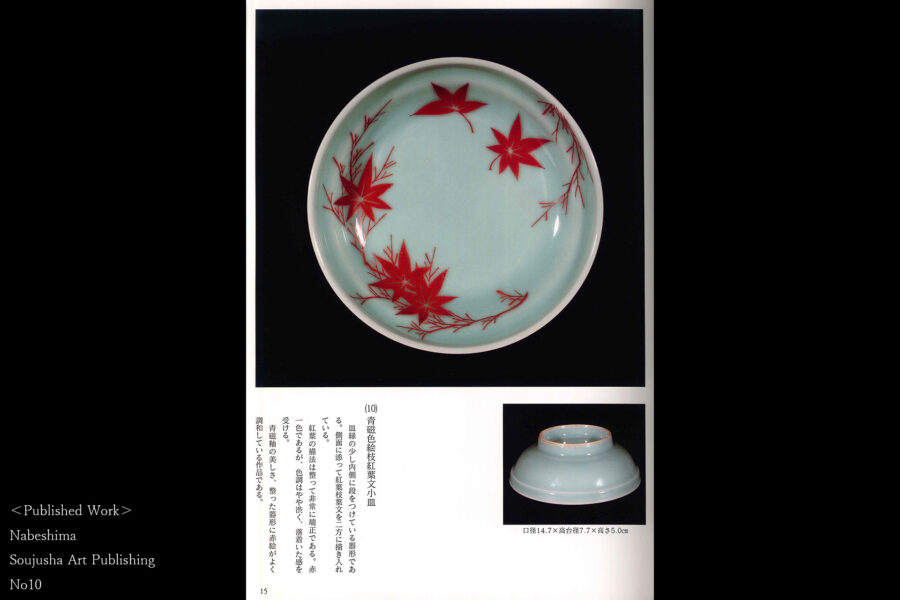

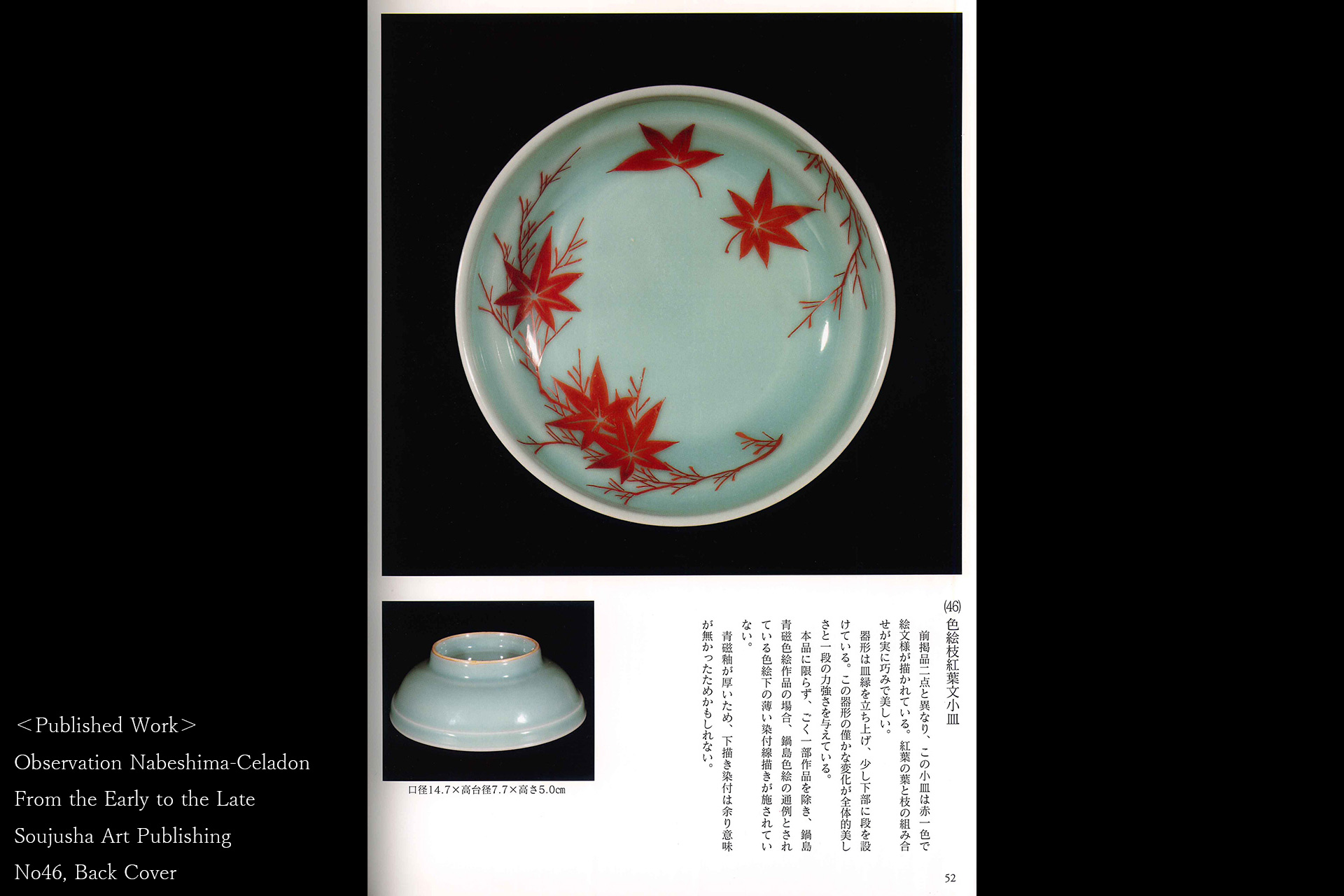

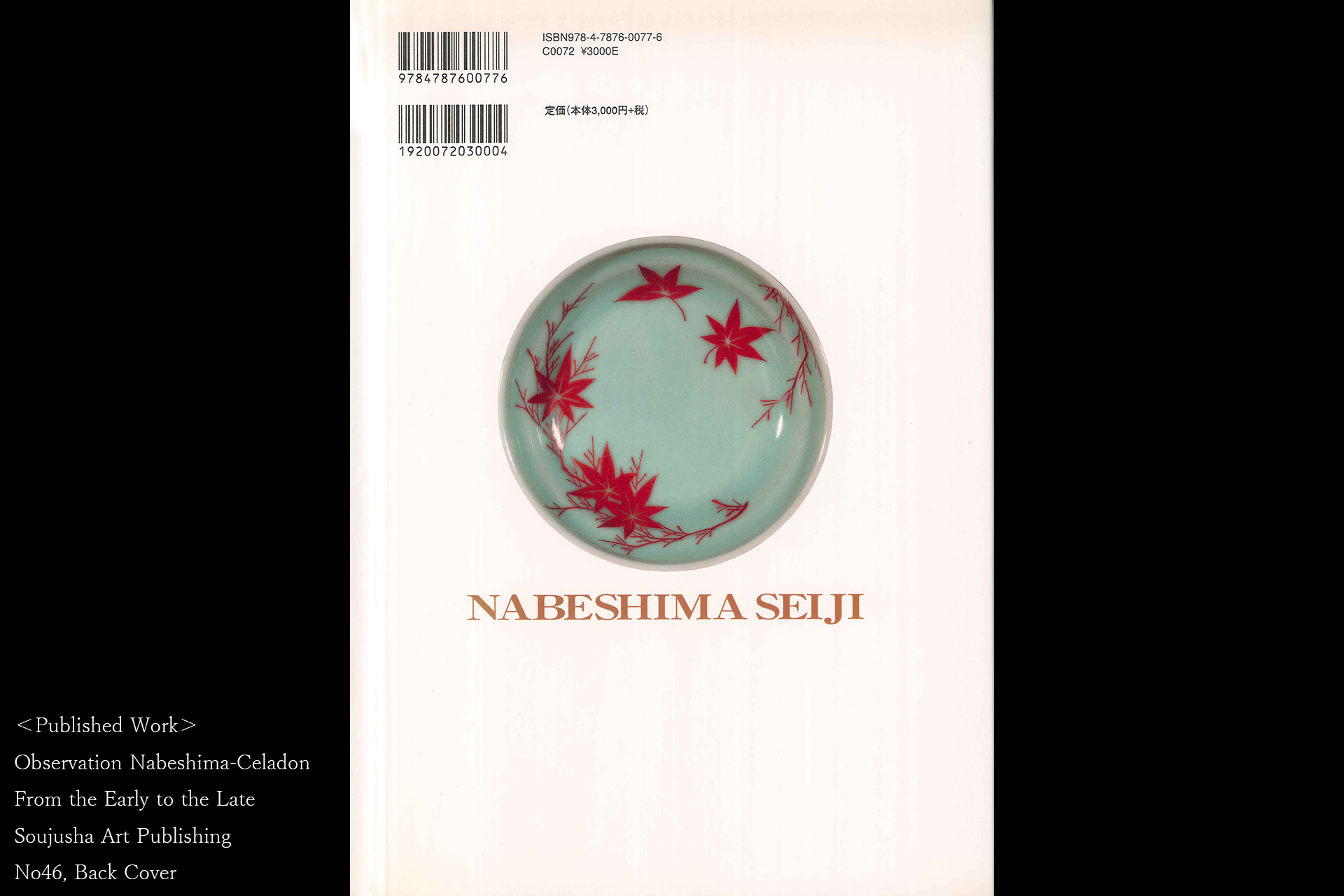

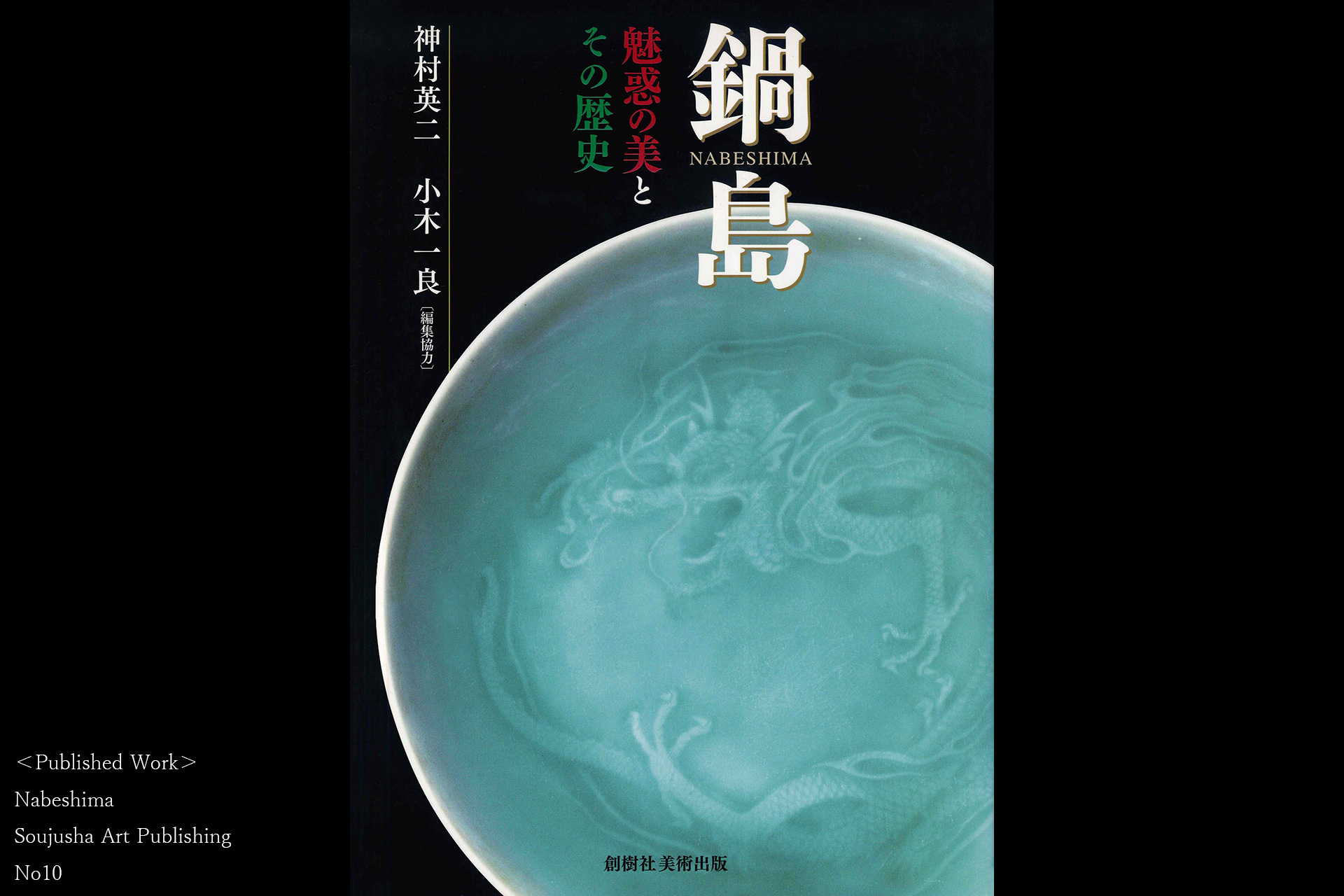

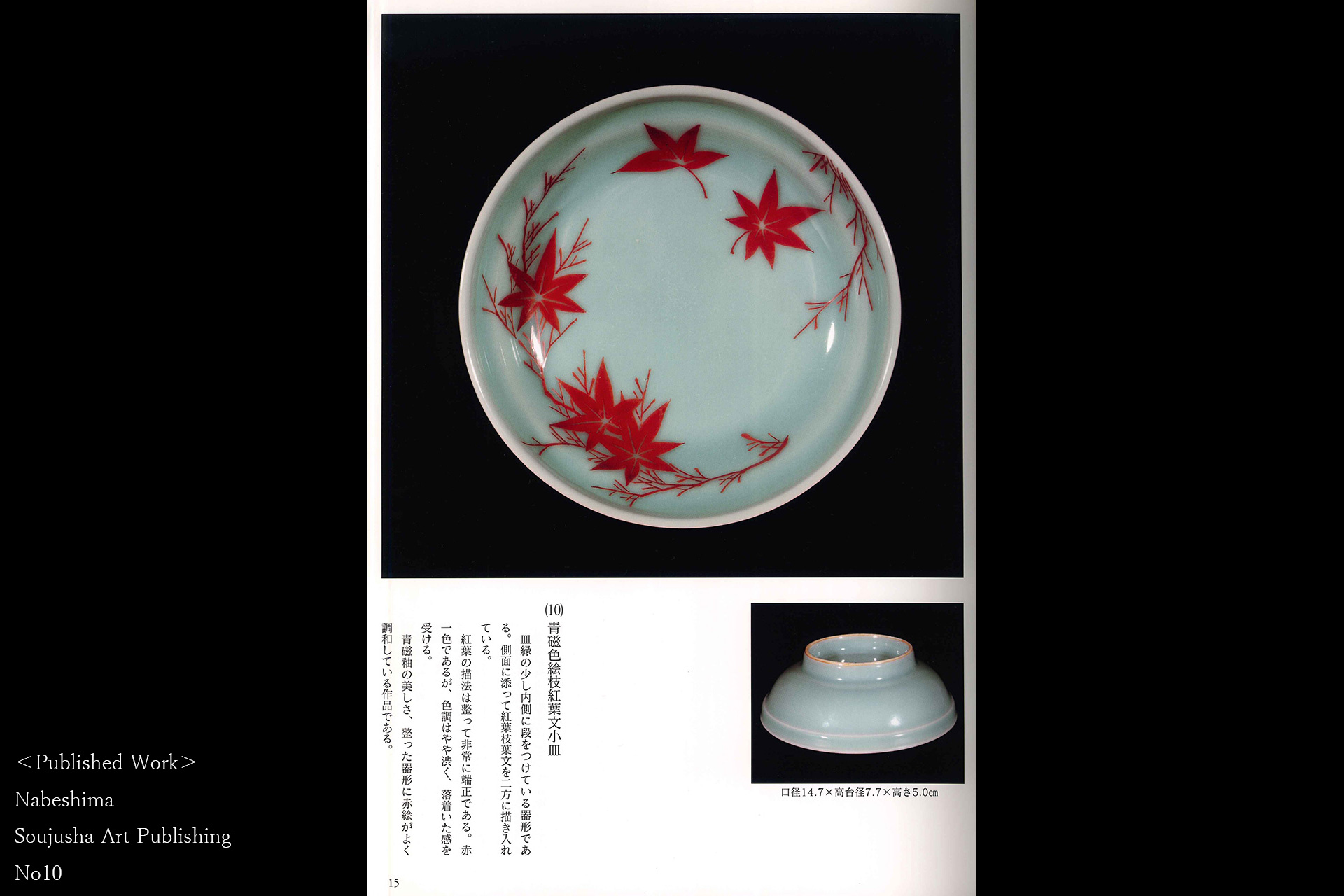

Nabeshima-Celadon Small Dish with Design of Autumn Leaves(Edo Period / Published Work)

Sold Out

This is the excellent work of nabeshima-celadon with a brilliant luster like a gem. The mysterious blue of the clear skies after rain, the deep red of the autumn leaves, and its solitary presence, endowed with dignity and elegance, captivated even the powerful people of the time.

Inquiry

- Product Code

- 250602-1

- Period

- Edo Period

Early 18th century

- Weight

- 333g

- Diameter

- 14.7cm

- Height

- 5.0cm

- Bottom Diameter

- 7.5cm

- Description

- Paulownia Box

- Provenance

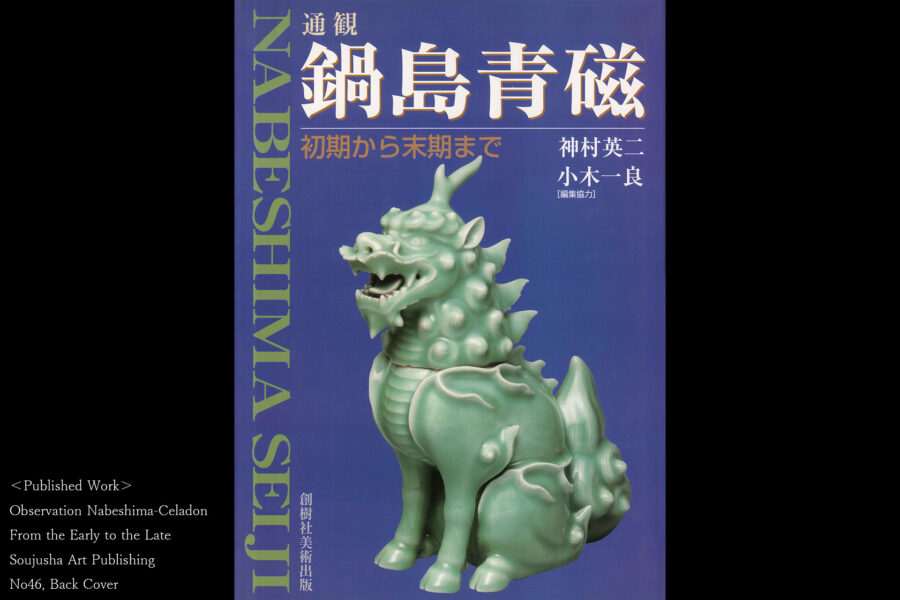

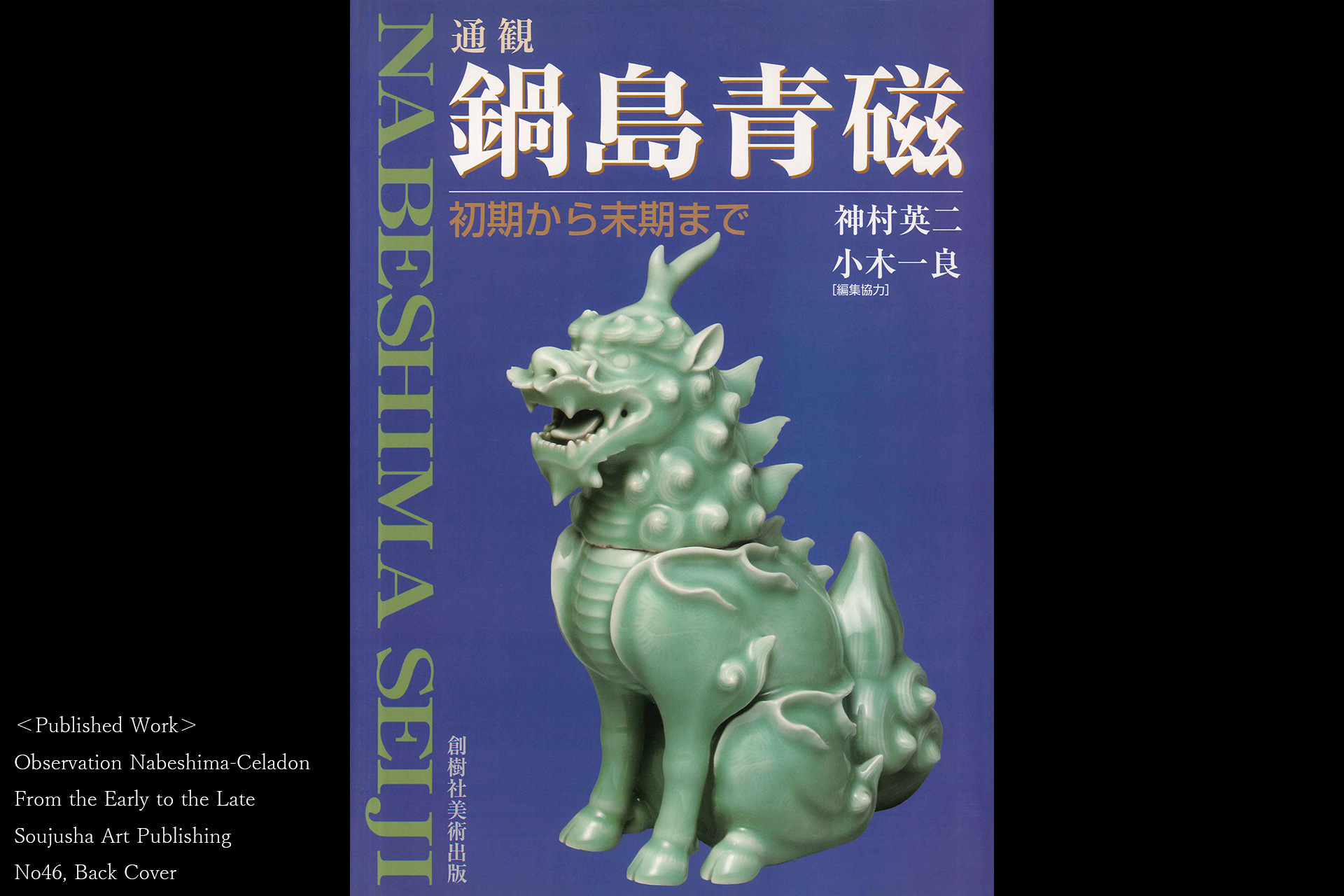

- 「Observation Nabeshima-Celadon From the Early to the Late」, Soujusha Art Publishing, No46, Back Cover, Published Work

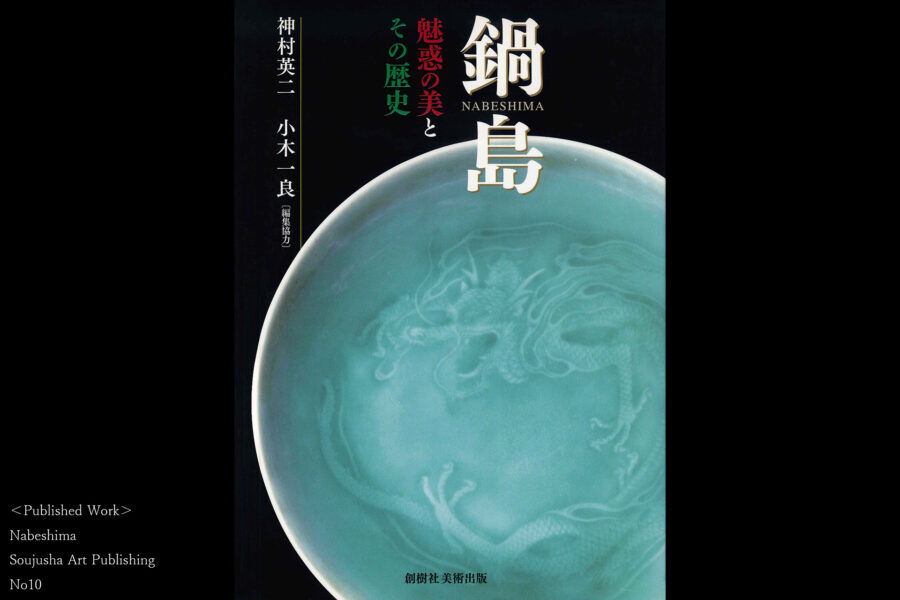

「Nabeshima」, Soujusha Art Publishing, No10, Published Work

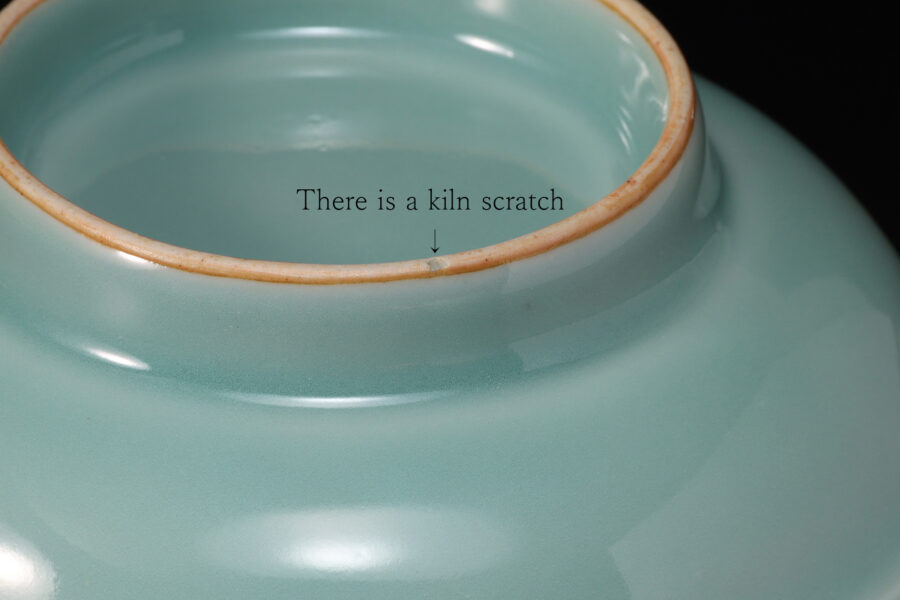

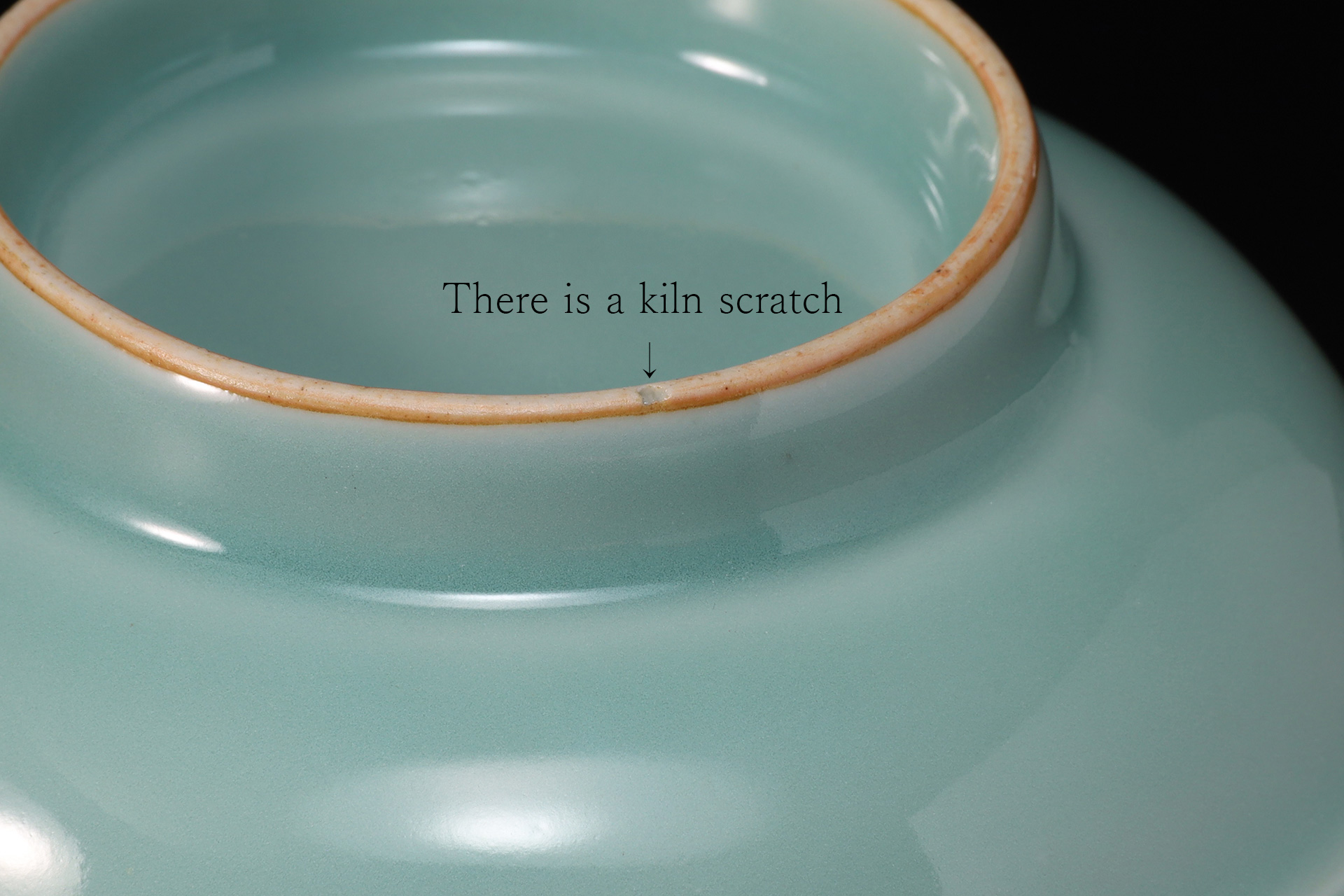

- Condition

- Excellent Condition(There is a kiln scratch at the bottom)

It meets the requirements of the first class work with its sophisticated modeling, beautiful celadon-glaze, and good firing. There is glaze inside the kiln scratch at the bottom.

Nabeshima Ware

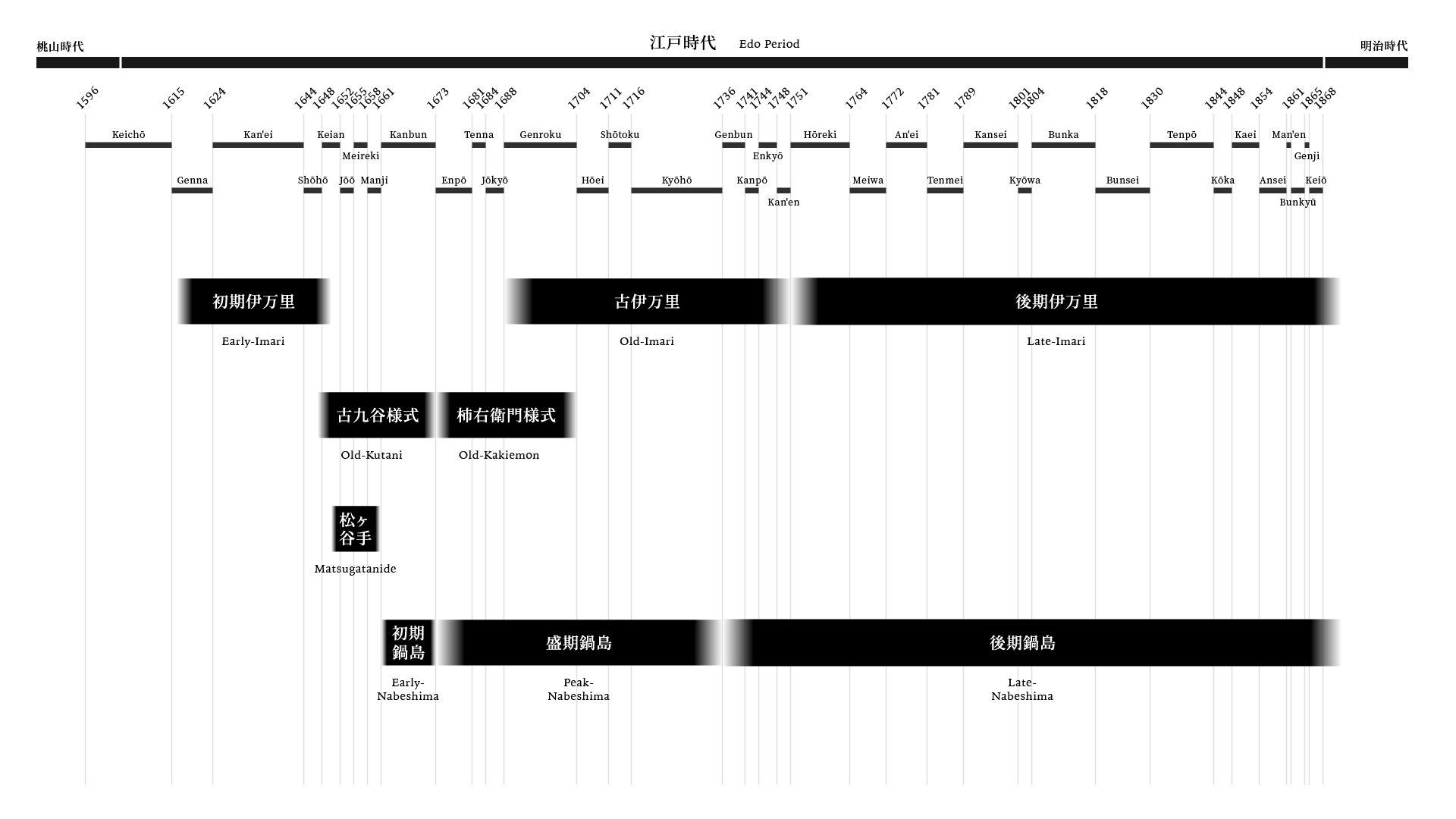

Nabeshima ware is an exquisite and prestigious specially made porcelain produced at the Nabeshima-domain-kiln in okawachiyama under the patronage of the nabeshima clan of the saga domain in hizen province. This porcelain produced by the nabeshima-domain-kiln, the only imperial-kiln in japan, is a world class masterpiece of porcelain, far superior to old-kakiemon in its technical mastery, and has established an extremely high reputation. It is no exaggeration to say that the highest quality pieces are on par with those produced by the Jingdezhen-imperial-kiln in china. By offering nabeshima ware to the tokugawa shogunate in edo, the nabeshima clan demonstrated its loyalty and obedience. They were also given outside the domain to maintain friendly relations with other feudal lords. Nabeshima ware, unlike imari ware, was not intended for sale but rather as a gift to neighboring regions, so its producers gave no regard to profitability. It is also noteworthy that these kilns did not follow the convention of producing vessels for tea ceremonies, as most clans’ kilns did, but instead focused on practical works, mainly dishes. In the hizen region, pottery production areas were called “Yama”. In the nabeshima domain, the kiln used by the offerings were to fire pottery was called “Odougu-Yama(Nabeshima-Domain-Kiln)”. These kilns were also called “Tome-Yama”, which means the lord’s kiln, to show the utmost respect. In the nabeshima-domain-kiln, the most skillful craftsmen from other kilns in hizen province were called in to establish the nabeshima clan’s unique style of kilns under strict control and in an environment separated from other kilns. According to records from the end of the edo period, 31 potters produced 5,031 pieces per year. These kilns took strict precautions to prevent secret techniques from leaking, such as setting up gates at the entrances and exits and prohibiting the passage of unauthorized visitors. Records tell us that all craftsmen working here were allowed to have family names and carry swords and were exempt from paying any public fees. To reach the site of nabeshima-domain-kiln, which is about 5km north in a straight line from the center of arita town, one has to take a long detour, which is more than 8km long. Such an environment sufficiently isolated the nabeshima-domain-kiln from the outside. Production was modeled after the jingdezhen-kiln in china, with a division of labor by specialty, where each craftsman did his best. Even a single dish went through the hands of many craftsmen. It is said that extra pieces were made in case of breakage during transportation and that 20 pieces were offered at a time. In the peak period, the kilns consolidated the most sophisticated techniques and methods. Blue-and-white, celadon are also well known, but the most famous was “Iro-Nabeshima”. Iro-nabeshima is outlined in paint, glazed with transparent glaze, fired at high temperature(blue-and-white), and overglazed within its frame with the primary colors of red, green, and yellow. This technique was based on the “Tousai” of the chenghua era(1465-87)of china’s ming dynasty. Because these works came from jingdezhen-imperial-kiln, the kilns could create highly sophisticated works without sparing any effort or regard for profit. The designs reflect japanese taste, departing from their chinese and korean influences, and feature unique and sophisticated designs centering on plants from the natural world. These works also draw inspiration from landscape paintings, noh costumes, and momoyama-edo period paintings. A typical vessel of this type is “Mokuhai-Shaped”. It features a high kodai(the bottom part that supports the vessel)made with a potter’s wheel. Kodai are thought to have taller bases than regular works from arita kilns to show their prestige. Many kodai works have a unique design called “Kushiba design(comb teeth design)” around the outer surface painted using blue-and-white. Generally, this technique was only allowed for the nabeshima-domain-kiln at that time and strictly forbidden in other kilns. In the peak period, these works employed a meticulous technique of painting inside the outlines drawn using blue-and-white. However, as time went on, the lines gradually became longer and the brushstrokes more disorganized, and a trend toward simplified, single line outlines gradually emerged. The works underwent several rigorous inspections by officers, and only those that passed were delivered to the clan, while any remaining rejected works were destroyed. The nabeshima-domain-kiln was dismantled in 1871 with the abolition of feudal domains and establishment of prefectures.

Nabeshima-Celadon

In japan, celadon (Karamono), which came from the continent, had been highly prized since the kamakura period, and the nabeshima ware had put particular emphasis on celadon. It is also known that the clan moved its kiln to okawachi-yama(nabeshima-domain-kiln) because of the availability of high quality celadon ore. The nabeshima clan thus produced some of japan’s finest celadons, which made a clear impression. Outstanding works bear a celadon color reminiscent of kinuta-celadon, the highest quality celadon produced in china. Nabeshima-celdon was designed to match the quality of the chinese kinuta-celdon and jiaotanxia-imperial-kiln celadon. The glaze consisted of natural celadon ore from okawachi-yama nihonyanagi mixed with the ashes from burning the best japanese cypress, which produced the soft, beautiful porcelain surface made during the peak-nabeshima. Although this celadon produced a deep color by applying multiple layers of the glaze, it had to be fired in a kiln each time, which entailed the risk of defects. Because the clan undertook the production of nabeshima ware, meant to be presented to the shogun and other feudal lords, it was possible to take such risks without regard to profit when firing celadon. While most common celadons only feature celadon-glaze, nabeshima-celadon uses the blue-and-white(sometsuke) technique(a technique of painting designs, applying a transparent glaze, and firing at a high temperature) and overglaze enamels. The celadon blue-and-white(sometsuke) for nabeshima using celadon-glaze containing gosu(a blue dye used for porcelain) has celadon-glaze applied at least twice, then gosu, along with another coating of celadon-glaze before firing. In this way, the works undergo a meticulous production process in which they are fired at least three times.